Yogurt is a product resulting from the fermentation of milk by two specific ferments: Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus.

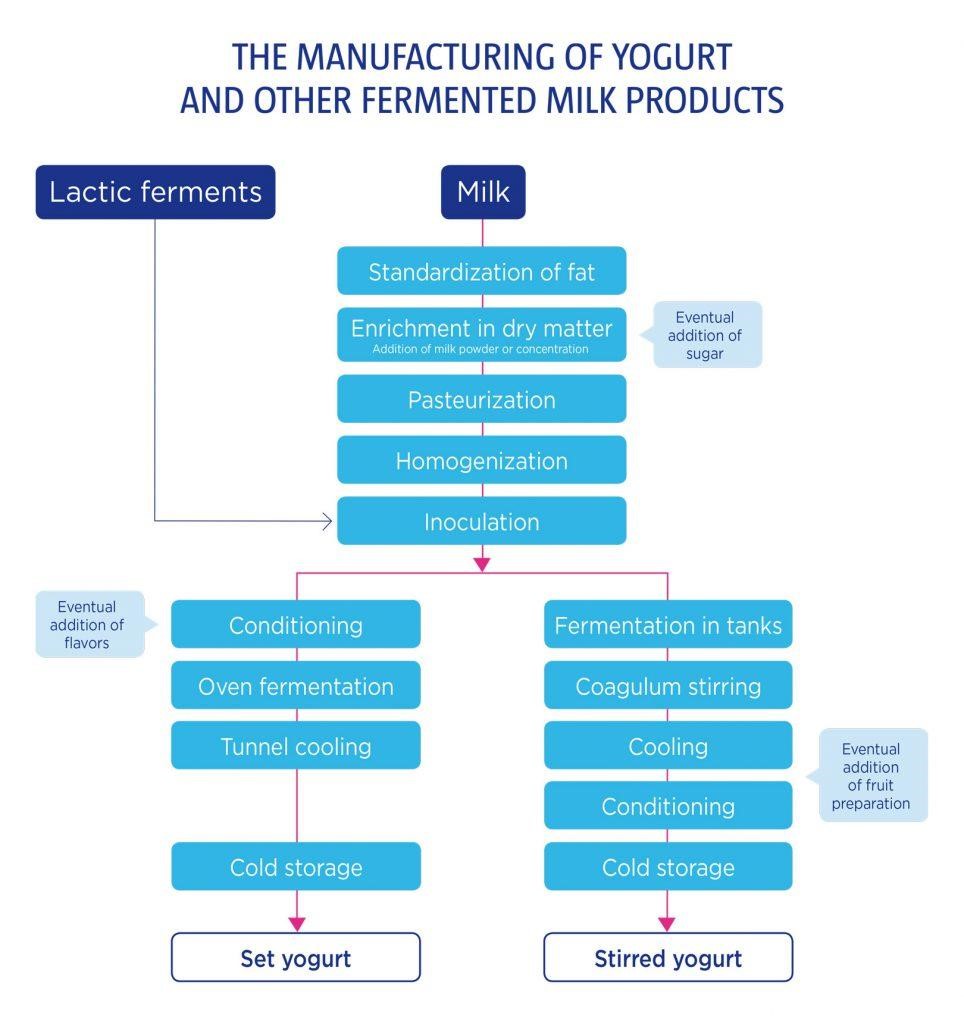

The raw milk is first transported from the farm to the manufacture. After standardization in fat (adjusting the fat content to a specific value), the milk is enriched in dry matter, by adding skim milk powder or whey proteins. The preparation is then pasteurized (176°F or 80°C for about 15 min.) and homogenized under high pressure. The homogenization prevent the cream from separating and rising to the surface. The fat content of the yogurt will depend on whether skimmed, semi-skimmed or whole milk will be used.

The pasteurized and homogenized milk has to cool to 109.4-114.8° F (43-46° C) and the fermentation culture is added in a concentration of about 2%. The culture consists of two specific lactic acid bacteria: Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus. Other cultures of selected bacteria can be added. However, in that case, the end-product will be called “fermented milk” and not “yogurt”.

Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus are the specific ferments of yogurt. These lactic bacteria will ferment the milk to obtain yogurt: they “digest” the lactose and produce lactic acid. This fermentation process generates consistency, flavor, aroma and health benefits. In fact, the live ferments in yogurt improve the lactose digestion (cf. opinion of Oct 19, 2010 from the European Food Safety Authority)

After cooling, several ingredients such as fruit preparations or sugar may be added to obtain a large variety of products.

The yogurt is then packaged and finally, the product is cooled and stored at refrigeration temperatures (40°F or 5° C) to slow down the physical, chemical and microbiological evolution.

It will result in many different types of yogurt : Greek yogurt, low-fat and no-fat yogurt, creamy, drinking, bio-yogurt, frozen, etc…